Sample Customization Commodity Plastic Injection Bucket Mould Manufacturers for 20 Liter Paint Round Pail Mold

Basic Info.

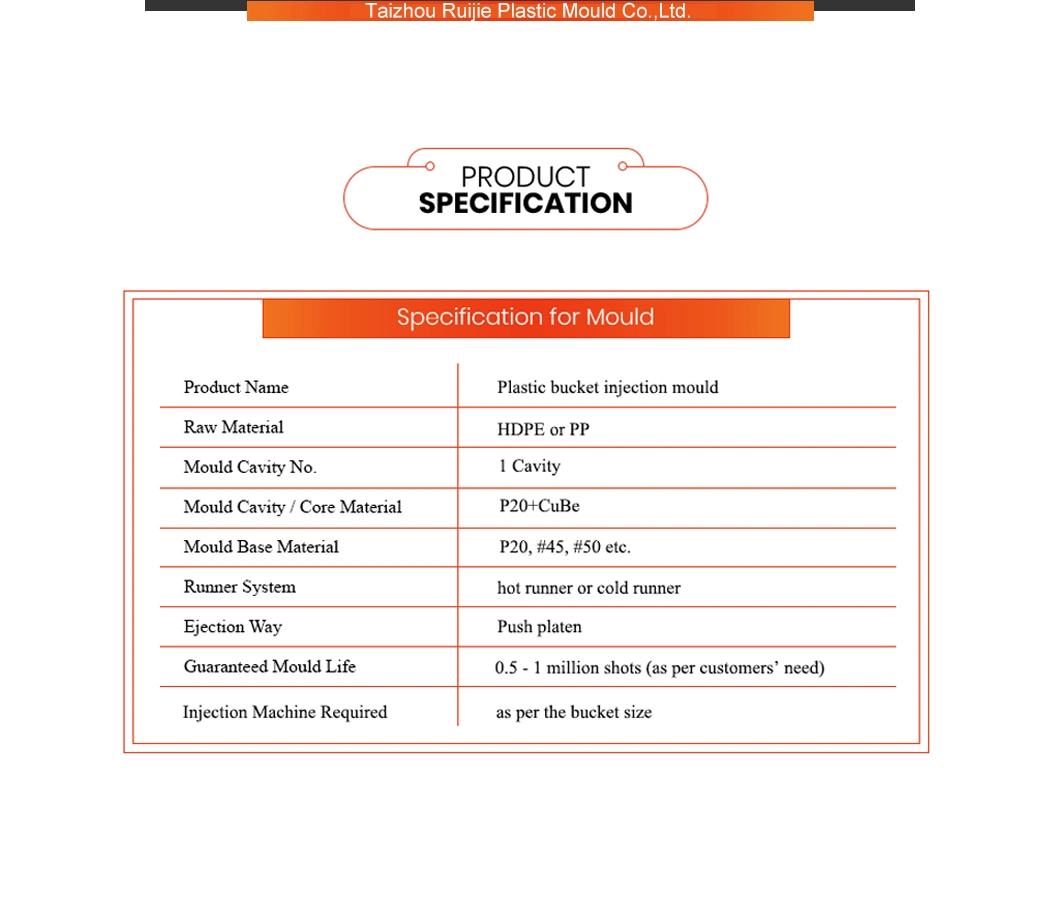

| Model NO. | RJBUM01 |

| Mould Cavity | Singer or Multi Cavity |

| Plastic Material | PP, PE |

| Process Combination Type | Single-Process Mode |

| Application | Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware, Food Storage |

| Runner | Hot or Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | CE, ISO, FDA |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | 1 Year |

| Bucket Thickness | as Per Customers |

| Cycle Time | 25s |

| Mold 3D Type | STP/Step/X-T/Igs |

| Mold Spares | Ejectors/Water Tips/Rings/Seal Rings/Heater etc |

| Delivery Time | 50 Days |

| Hot Runner Brand | Yudo (or as Per Customer) |

| Mold Life | 0.6 Million Shots |

| Transport Package | Wooden Box |

| Specification | Customized |

| Trademark | ruijie |

| Origin | China |

| HS Code | 8480719090 |

| Production Capacity | 20 Sets/Year |

Packaging & Delivery

Package Size 900.00cm * 700.00cm * 600.00cm Package Gross Weight 1000.000kgProduct Description

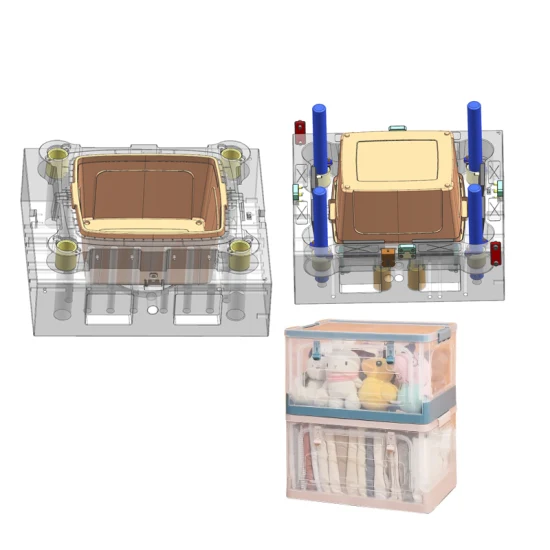

Bucket Mould Manufacturer

RJ Mould is one of the leading plastic bucket mould manufacturers in China. We are professional in plastic paint bucket mould, water bucket mould, baby bucket mould, food bucket mould, mop bucket as well as other types of plastic buckets.

For the bucket sizes, our current bucket sizes range is from 1 liter and up to 30 Liters. We are also very capable to do customized bucket moulds for other capacity.

Our factory offers a large variety of bucket shape options, the available shape includes, square, rectangular, oblong, oval and round plastic buckets.

Process of Bucket Mould Manufacturing

1. Plastic Bucket Design

2. 3D sample confirmation

3. Bucket Mold Design

4. Bucket Injection Mold Making

5. Mold Trial

6. Injection molded bucket manufacturing(if needed)

How to Ensure the Quality of Bucket Mould?

With over 10 years of experience in designing and manufacturing bucket molds, we know every details of bucket mold well and always keep "quality is 1st important" in mind during the mould manufacturing period.

Our team will study the bucket design to make sure a prefect mould struture.

As per customers' requirement, we will suggest the suitable steel material.

Before mold delivery, we will arrange at least 3 times of mold testing to ensure smooth mold running process and to get high quality bucket samples.

Quality plastic pail paint bucket mould

1. Bucket features: 100% sealing and are great for packaging grease, paint, food and so on.2. Bucket size: from 1 gallon to 5 gallon3. Bucket Material: new or recycled polypropylene (PP), polyethylene (PE).4. Mould material: H13, 718, P20 etc5. Mould cavity number: will be suggested by customers' injection machine tons.Usually, one cavity for bucket body, 1 cavity for bucket lid, 2 cavities for hanlde6. Runner system: Hot runner or cold runner7. Delivery time: 50 - 70 days Mould manufacturing and bucket mass production are all available at RJ factory. We could support for different testing according to project requirement, the common testing for the paint bucket samples include stacking ability,weight tolerance, Water seal, Drop test etc.

Other Plastic Bucket Moulds

Our Main Mould

1Q: Are you trading company or manufacturer ?

A: We are factory and located in Taizhou City, Zhejiang Provice, China.2Q: What kind of service do you offer?

A: We can make all kinds of plastic injection moulds. Customized mould project are also welcomed in RJ Mould.Besides, we have our own injection machine and can do mass production for customers too.3Q: What information is required for a quote? A. Please provide us with product 2D or 3D drawing.If you don't have drawings on hand, samples are also available for checking cost.4Q: Can I have my own design?

A: Yes, we are very capable to do customized design and make for you. Please share with your ideas, we will discuss your needs, purpose and objective thoroughly and work together with you for the whole project.5Q: How long is your delivery time?

A: The lead time of T0 sample depends on the mould structure, and generally it takes 20-70 days from receipt/approval of final drawings, deposit and mold design approval.Mass production delivery time depends on the order quantity.6Q: What's your payment condition?

A: For Mould: T/T, 40% Deposit with P.O., balance before shipment. Or 100% irrevocable LC at sight.Part molding: 50% after PO confirmed, 50% after production finished.7Q: What Hot Runner Brand will you use?

A: As per customers' demands, we can offer YUDO or Chinese local brand hot runner system.8Q: What's your injection mould life?

A: 0.5 to 3 million shots guarantee, depends on your needs.9Q: What's the shipping cost? And how long it takes for shipment?

A: Please let us know,1. Shipment method, do you prefer by sea or air?2. Destination port or door to door address with ZIP code.We will check and find the best price for you.