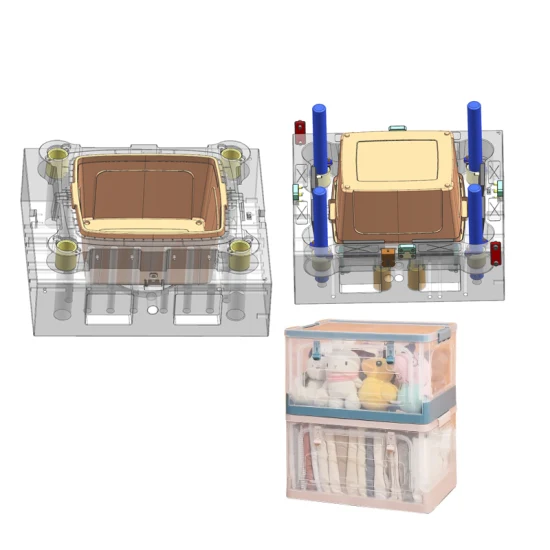

Injection Mold for Transparent / Clear Color Housing of Coconut Juicer Cooking

Overview Package Size 45.00cm * 66.00cm * 42.00cm Package Gross Weight 720.000kg Prototype Making Mold for PETS Material;

Overview

Work Shop

Basic Info.

| Model NO. | HW-1195 |

| Mould Cavity | Multi Cavity |

| Plastic Material | ABS |

| Process Combination Type | Compound Die |

| Application | Household Appliances, Furniture, Commodity, Electronic, Home Use |

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | ISO |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | Any Question Please Feel Free to Contact Us. |

| Molding Material | ABS, PETG, PP, PC, PE, POM, PMMA, PS, etc |

| Plastic Injection Machine | 90t, 110t, 140t, 160t, 200t, 260t, etc. |

| One Stop Service | Workable |

| Lead Time | 7-14 Days for Samples, 25-40 Days for Mould |

| Mold Cavity | Single Cavity / Family Molds / Multi Cavity |

| Mold Life Time | 300, 000~1, 000, 000 Shots |

| Design Sofeware | Ug, Proe, CAD, Solidwork, etc |

| Name | Plastic Injection Molding |

| Transport Package | Wooden Cases/Air/Sea |

| Specification | Custom |

| Trademark | HOWE or Custom |

| Origin | China |

| HS Code | 8522901000 |

| Production Capacity | 40sets/Month |

Packaging & Delivery

Package Size 45.00cm * 66.00cm * 42.00cm Package Gross Weight 720.000kgProduct Description

Prototype Making Mold for PETS Material Juice EnclosureProduct Description| Product name | Multi cavity hot runner injection mould supplier |

| Mould Material | P20,P20H,718,718H,738,738H,2316,M300,S136,S136H,NAK80,CR12,CR12MOV,SKD11,DF-2,SKS3,D2,SLD,DC53,H13,SKD61,2344,8407,HD,8418,FDAC,M2,SKH-9,SKH-51,M35,M42,ASP23 |

| Main Technology | Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

| Base material | P20, 2738, 2344, 718, S136, 8407, NAK80, SKD61, H13 |

| Product Material | ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS, TPV, TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF |

| Main Technology | Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

| Equipment | CNC, EDM, Cutting off Machine, plastic machinery, plastic part, etc |

| Mould Cavity | One cavity, multi-cavity or same different products be made together |

| Runner System | Hot runner and cold runner |

| Finish | Pitting the word, mirror finish, matte surface, striae |

| Mould Life | 300-500K shots |

| Mould Precision | +/-0.05mm--+/-0.1mm |

| Producing Process | Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending |

Work Shop

Howe's value-added injection molding services include, but not limited to,

•Material selection and design advice

•Prototyping and production

•Plastic parts and component

•Secondary processes

•Ultrasonic welding

•Silk printing and Pad Printing

•Assemblies and Package

You may also like

Send inquiry

Send now